It’s then further allocated to the departments that use the procurement facility. Further, overhead estimation is useful in incorporating seasonal variation and estimate the cost at the start of the project. On the other hand, if the business wants to use actual overheads, it has to wait for the end of the month and get invoices in hand. So, it may not be a good idea with perspective to effective business management. Businesses normally face fluctuation in product demand due to seasonal variations.

Distinguishing Between Overhead, Direct Costs, and Manufacturing Overhead

Additionally, underapplied overhead can affect the accuracy of financial ratios, such as the gross profit margin and return on investment. This applied overhead is then added to the direct materials and direct labor costs to determine the total cost of the job. Applied overhead represents the amount of overhead costs that are assigned to products or services Mental Health Billing using the predetermined overhead rate. The choice of cost driver should be logically related to the overhead costs being allocated. For example, if a large portion of overhead costs consists of depreciation on machinery, machine hours might be the most appropriate cost driver.

Examples Using Direct Labor Hours and Machine Hours

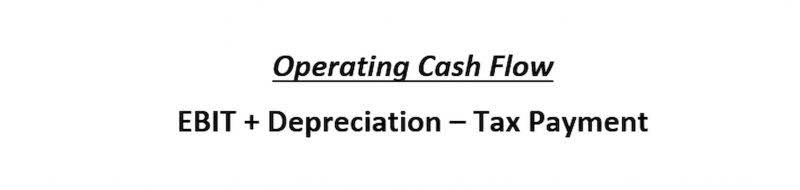

This section delves into the methodologies used to apply overhead costs to products, a critical step in determining product profitability and making informed business decisions. Overhead costs, on the other hand, are indirect costs that cannot be easily traced to a specific product or service. Traditionally, overheads have been absorbed in the product cost based on a single basis of apportionment. For instance, in a labor-intensive environment, labor hours were used to absorb overheads. On the other hand, the machine hours were used to absorb overheads in a machine incentive environment. A predetermined overhead rate (pohr) is use to calculate the amount of manufacturing overhead which is to be applied to the cost of a product.

Conclusion: Mastering Overhead Rate Calculation for Improved Financial Health

We can calculate predetermined overhead for material using units to be allocated. For example, we can use labor hours worked, and for calculating overhead for the store department, we can use the quantity of material to be used. Implementing predetermined overhead rates involves key steps for accurate cost allocation. The use of such a rate enables an enterprise to determine the approximate total cost of each job when completed. In recent years increased automation in manufacturing operations has resulted in a trend towards machine hours as the activity base in the calculation. Even for startups, having a basic understanding of your overhead costs is crucial.

Question: Bronzit Company estimated the following at the beginning of the

After going to its terms and conditions of the bidding, it stated the bid would be based on the overhead rate percentage. Therefore, the one with the lower shall be awarded the auction winner since this project would involve more overheads. Two companies, ABC company, and XYZ company are competing to get a massive order that will make them much recognized in the market. This project is going to be lucrative for both companies but after going over the terms and conditions of the bidding, it is stated that the bid would be https://blocktrons.com/invoice-and-accounting-software-for-small/ based on the overhead rate.

What is the Predetermined Overhead Rate and Why is it Important?

These rates, calculated before the accounting what is the predetermined overhead rate period begins, offer a systematic approach to incorporating overhead into the costing process. They provide a stable and predictable method that avoids the fluctuations inherent in using actual overhead costs. A predetermined overhead rate is an estimated rate businesses use to apply manufacturing overhead costs to products or services, established before actual costs are known. Its purpose is to enable timely product costing, allowing companies to determine approximate total costs as production occurs, rather than waiting until the end of the accounting period. One of the most effective ways to prevent underapplied overhead is to allocate overhead costs accurately.

- Adjustments are typically made at the end of an accounting period, but significant events may warrant more immediate revisions.

- This provides a more accurate representation of inventory values and cost of goods sold.

- The downside is that it increases the amount of accounting labor and is therefore more expensive.

- For this, you can take the average manufacturing overhead cost for the previous three months, and divide this by the machine hours in the current month.

- The process of calculating a predetermined overhead rate is a meticulous task that requires careful consideration of various factors.

- For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March.

- Analyzing overhead rates by department in this manner helps identify problem areas and opportunities to improve profitability.

- Its purpose is to enable timely decision-making regarding pricing, budgeting, and cost control.

- Finally, predetermined overhead rates can be difficult to update on a regular basis, which can lead to outdated information being used in decision-making.

- This will result in a lower gross profit and a more accurate representation of the total cost of production.

- Ultimately, it is essential for companies to accurately estimate their overhead costs and production levels to avoid underapplied overhead and ensure accurate financial reporting.

Therefore, this predetermined overhead rate of 250 is used in the pricing of the new product. The predetermined rate is based on estimates before the accounting period begins and is held constant throughout the period. The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used. Carefully minimizing overhead is crucial for small businesses to maintain profitability. Following expense optimization best practices and leveraging technology keeps overhead costs in check. Knowing the overhead cost per unit allows the business to set competitive pricing while still covering their indirect expenses.

The company, having calculated its overhead costs as $20 per labor hour, now has a baseline cost-per-hour figure that it can use to appropriately charge its customers for labor and earn a profit. That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100. In other words, using the POHR formula gives a clearer picture of the profitability of a business and allows businesses to make more informed decisions when pricing their products or services. In this article, we will discuss the formula for predetermined overhead rate and how to calculate it.

No Comments